To reduce the number of product defects, Harry and Smith created the original statistics and formulas as a quality management tool. Six Sigma was famously started at Motorola in the 1980s by Mikel Harry and Bill Smith, two engineers who developed the methodology to improve operations on the manufacturing floor. However, the term “Six Sigma” did not come into play until the 1980s. In the mid-1900s, Boeing, Ford, and Toyota began experimenting with Lean manufacturing, a process aimed at reducing waste while maximizing productivity in their plants. Anything that deviates from three sigmas means it needs improvement, and “Six Sigma” refers to improving defects to 3.4 for every 1 million units of product. Six Sigma is named as such because one sigma is one standard deviation in a bell curve. Six Sigma focuses on meeting the needs of customers while improving business productivity.

#Methods used to measure six sigma processes how to

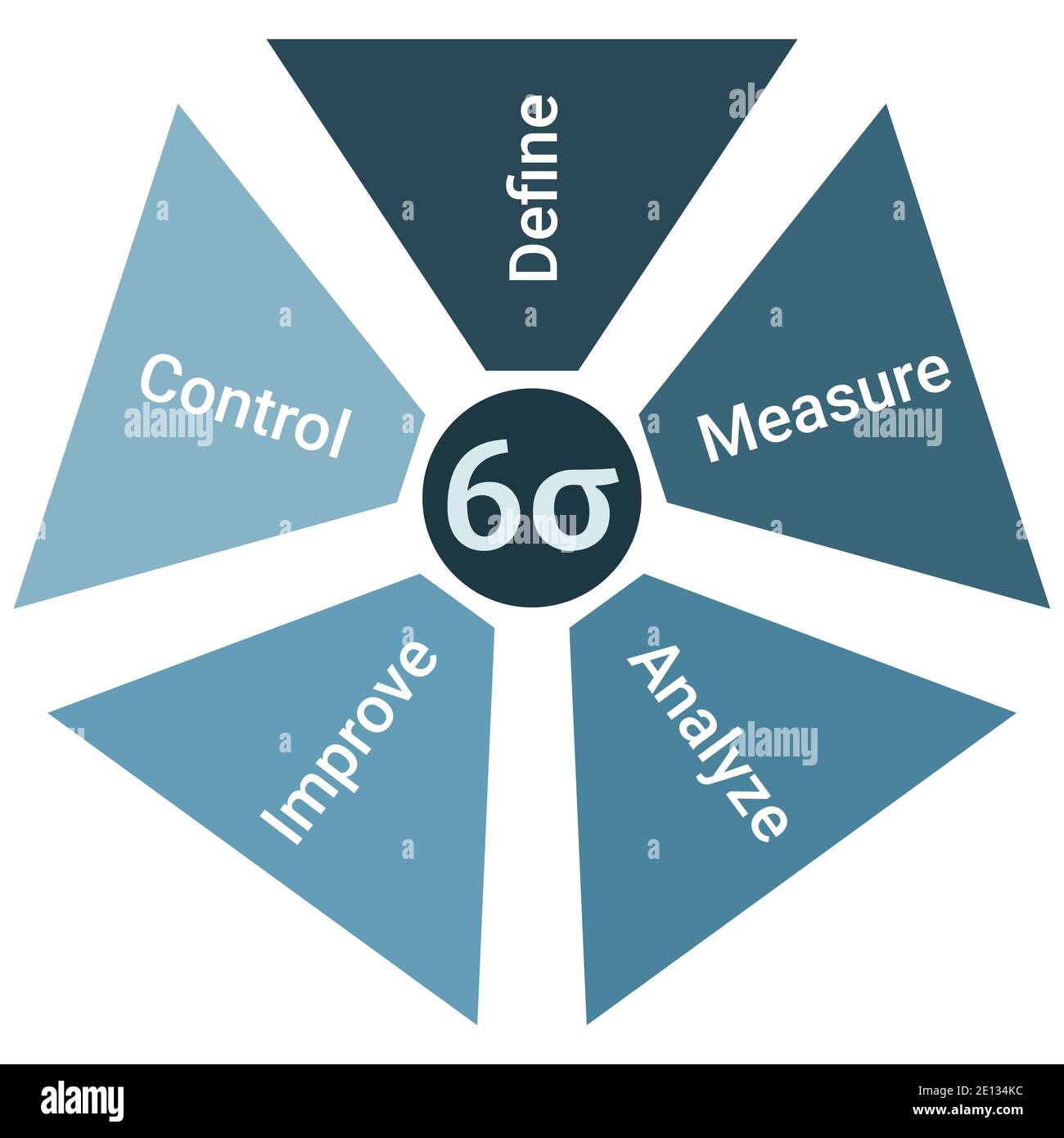

Six Sigma is defined as a method to improve business capabilities by systematically looking at flaws and how to fix them. This means that certified professionals are in high demand.Īt its core, Six Sigma is a process improvement tool that leverages data and objective problem-solving.

The Lean Six Sigma methodology has permeated a variety of industries around the world, from manufacturing plants to pharmaceutical companies to the financial industry.

A total of 53 percent of Fortune 500 businesses use Six Sigma to save an estimated $427 billion. As businesses worldwide look to streamline processes and increase efficiency, more and more companies are becoming interested in Six Sigma methodologies, a popular process improvement methodology.

0 kommentar(er)

0 kommentar(er)